Rebar fabrication process is carried out at INGETEK's facilities using a fully automated system defined by a high level of safety and quality standards, high-speed execution times, and just-in-time deliveries:

Rods are fabricated within standards and limits established in the dimensional control.

aSa forms, reinforced concrete elements in general.

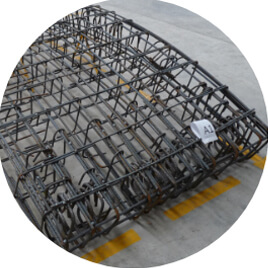

Is a prefabricated assembly for concrete reinforcement, optimizing the required amount of steel and speeds-up the constructive process by its fast placement.

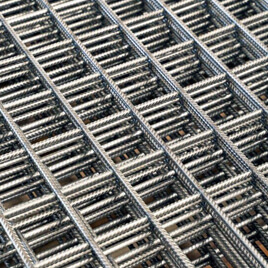

Engineered Structural Mesh | Data sheetFloors, walls, segments, canals, footings, tunnels, slabs, prefabrication

Used for easily connecting rods by threading their ends.

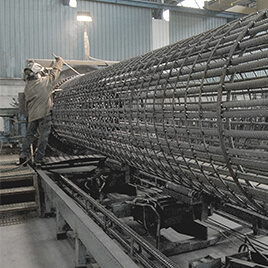

Foundations, pile rebar cages, walls, floors, prefabricated.

Structures fabricated in semiautomatic machinery under an industrialized process with standardized measures. INGETEK has a wide variety of cages with different diameters and lengths, according to each project.

Foundations.

One-piece, fully assembled elements prefabricated at the worksite.

Bridges.

Ingetek’s method for this product consists in the fabrication of a frame mainly used in tunnel construction through engineering and own constructive methods to provide our clients a complete solution.

Bridges, tunnels and tunnel segments.